Customer Value

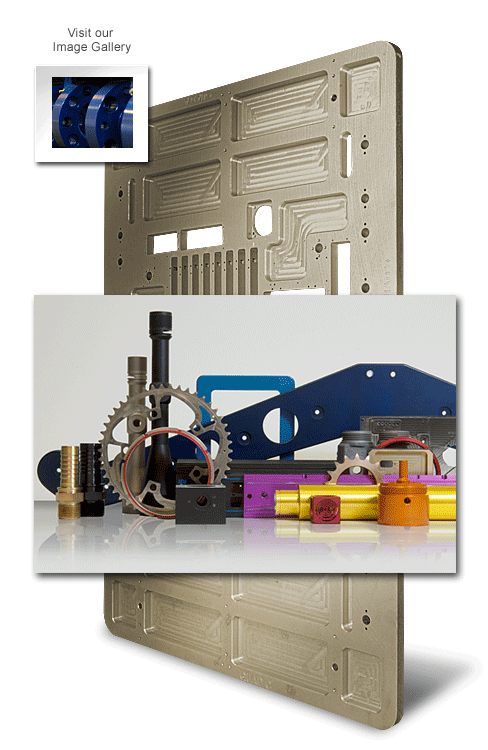

We enhance the surfaces of your metal part to achieve your predetermined physical and aesthetic characteristics. In addition, our finishing processes extend a part's lifespan, protect against corrosion and wear, enhance its electrical properties, form and shape while improving its bonding ability to adhesives and organic coatings.

Download our Terms & Conditions (PDF)

For customers with large needs, we offer dedicated lines and processes for both simple and complex jobs. At the same time, these lines provide smaller customers with a cost-effective way to complete your product manufacturing process. For all customers, we strive to provide consistent, high quality services that satisfy your delivery needs.

Finishing Professionals offers four types of finishing processes:

• Electroplating

• Anodizing

• Electroless Plating

• Chemical Conversion

We regulate each process by controlling:

• Voltage and Amperage

• Temperature

• Dwell times

• Purity of bath solutions

All our plating baths are aqueous solutions comprised of reagents with varying chemical compositions and concentrations.

We process your parts:

• By hand

• On racks which carry parts from bath to bath

• In barrels which rotate in a plating solution

• On carriers which are computer-controlled and automated

We perform our finishing processes and applications on seven separate plating lines.

Electroplating

Electroplating applies a plating film or coating to metal parts by creating an electrical movement. We pass an electric current through an aequeous solution containing dissolved metal ions and the target part. The target part serves as the cathode (terminal through which an electrical current leaves an electrolytic cell) and attracts ions from within the electrochemical bath.

Eletroplating is used for depositing a layer of material that bestows a desired property characteristic (e.g., abrasion and wear resistence, corrosion protection, lubricity and aesthestic qualities) to a surface that is otherwise lacking. Electroplating also can build up thickness on undersized parts.

We use this process to plate ferrous and non-ferrous metal parts with the following metals:

• Nickel

• Matte Tin

• Bright Tin

• Zinc